After years of being relegated to jobs with low graphics requirements, flexography now rivals other printing methods for quality and efficiency thanks to advances in the ink delivery process. Specifically, doctor blade chamber systems allow for better control over ink film thickness, color consistency, ink consumption, cleaning costs and press run time.

After years of being relegated to jobs with low graphics requirements, flexography now rivals other printing methods for quality and efficiency thanks to advances in the ink delivery process. Specifically, doctor blade chamber systems allow for better control over ink film thickness, color consistency, ink consumption, cleaning costs and press run time.

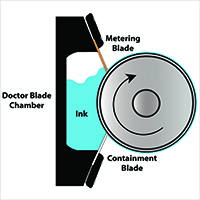

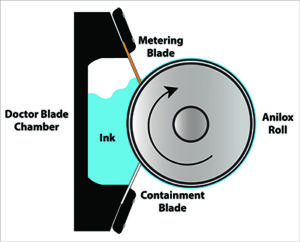

A chamber doctor blade system uses two doctor blades along with an enclosed ink chamber to dispense the ink to the anilox roll. The reverse angle blade acts as the metering blade and wipes excess ink from the anilox roll, and the trailing blade acts as a capture or containment blade and holds the ink within the chamber. Foam, rubber or felt gaskets seal both ends of the chamber and keep ink from leaking out.

The enclosed chamber design provides protection from evaporation of solvents or amines from the ink, depending on whether the ink is solvent or water-based, so a printer can maintain ink viscosity. Also, the ink is sheltered from dust, and slinging and skimming on the surrounding area are minimized. Better control over ink usage means lower ink consumption by as much as 15% per year. The system holds less ink than open pans, so there is less leftover ink at the end of a press run, and this ink can be removed and stored for future use.

Doctor blade chambers also allow for a more efficient and eco-friendly cleaning process than open ink systems. A smaller amount of cleaning solution and water are needed, so cleaning solution and water usage are reduced along with disposal costs. Color changes are quick, speeding up changeover and setup time on a run.

Recently, chamber producers have incorporated innovative engineering concepts and next-generation materials to improve the equipment’s performance and usability. New carbon-fiber constructions are lightweight, strong, durable and temperature-stable, and they reduce press vibrations even on wide format presses. Their surfaces are coated with resin to provide anti-static, corrosion-resistant properties. Advanced clamping systems, like TRESU’s E-Line and P-Line Systems, replace screws with eccentric and pneumatic apparatuses, respectively, to make blade changes faster and easier for operators.

Recently, chamber producers have incorporated innovative engineering concepts and next-generation materials to improve the equipment’s performance and usability. New carbon-fiber constructions are lightweight, strong, durable and temperature-stable, and they reduce press vibrations even on wide format presses. Their surfaces are coated with resin to provide anti-static, corrosion-resistant properties. Advanced clamping systems, like TRESU’s E-Line and P-Line Systems, replace screws with eccentric and pneumatic apparatuses, respectively, to make blade changes faster and easier for operators.

Early chamber systems were designed for use with steel blades. But, to address the increasing demand in the industry for plastic doctor blades, TRESU worked closely with doctor blade manufacturer Flexo Concepts® to develop the exclusive new Series XL Blade Holder. The interchangeable

quick-change clamp apparatus can accept slightly thicker TruPoint® plastic doctor blades, giving printers access to a much wider variety of blade options. Those who prefer plastic blades over steel – whether to improve safety, extend blade life or solve press problems like UV ink spitting – have the flexibility to use plastic or switch back and forth between materials based on job requirements.

When selecting a doctor blade chamber, there are several factors to consider in order to maximize the return on investment. The doctor blade chamber and its loading system should prevent blade misalignment and ensure even contact across the face of the anilox roll. It is also important to make sure that the system allows operators to adjust pressure between the doctor blade and anilox roll. Minimum pressure, particularly when using TruPoint blades, is important to optimize print quality, prolong blade life and preserve anilox integrity.

Today’s flexo printers are able to produce attractive packaging in a cost-effective way thanks in part to the benefits provided by doctor blade chambers. These enclosed systems contribute to high print quality and bring considerable efficiency and cost savings to the pressroom. Along with cutting-edge press, ink, substrate and doctor blade innovations, advances in chamber technology have further improved the ink delivery process, making flexography a viable option for today’s most demanding print applications.