Flexo Concepts® to Promote Its MicroTip® Doctor Blade Edge Technology at Drupa 2016

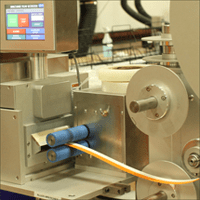

Christine Duggan2024-03-19T10:30:28-04:00Plymouth, MA, May 13, 2016. Flexo Concepts will introduce a variety of new MicroTip options on its TruPoint Orange® doctor blade at Drupa 2016 in Dusseldorf, Germany. [...]