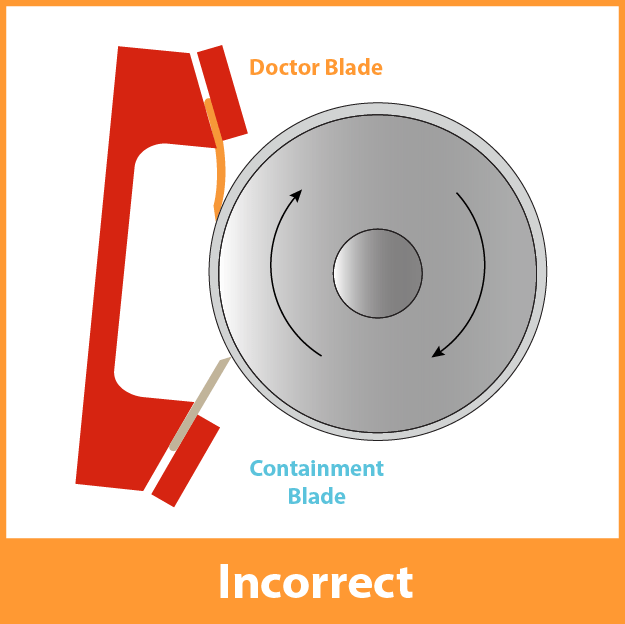

Steel Doctor Blades Cause Anilox Roll Scoring and Injuries

Christine Duggan2020-07-31T09:15:03-04:00Steel doctor blades are often the cause of anilox roll scoring and severe personal injuries. Switching to nonmetallic blades can not only ensure print quality and minimize [...]