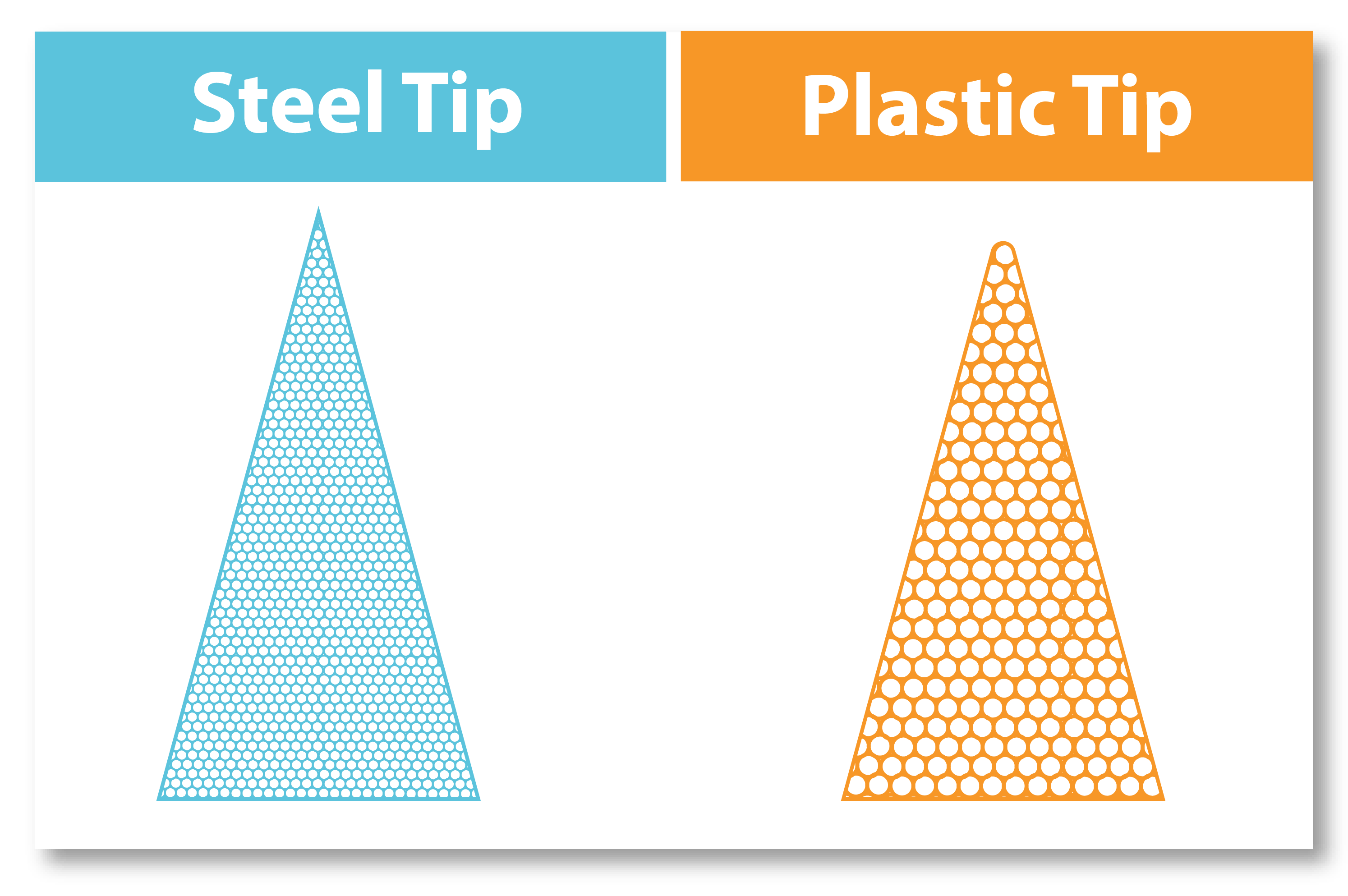

Everyone agrees that plastic doctor blades are safer than steel. But why exactly is this true? The answer lies in the fundamental differences between the two materials: steel blades are harder and sharper than plastic blades. While this is commonly understood, the reason becomes clear when we examine the molecular structures of these materials.

Everyone agrees that plastic doctor blades are safer than steel. But why exactly is this true? The answer lies in the fundamental differences between the two materials: steel blades are harder and sharper than plastic blades. While this is commonly understood, the reason becomes clear when we examine the molecular structures of these materials.

What Does It Mean to Be Sharp?

Steel and plastic materials (and all matter) are comprised of small particles. As a doctor blade wears, the material is removed in clusters of particulate which can be no smaller than the basic particle size of the material. So, the finest tip on a blade can only be as wide as one particle. And since plastic particles are larger than steel particles, a plastic blade worn to its finest point will be wider than steel. This combined with the fact that plastic is inherently softer than steel, results in a plastic blade edge that is less “sharp” than steel and safer to handle.

Ink Metering with Plastic Blades

Given this information, one might wonder if plastic blades can wipe as effectively as a steel blade. The answer is some can, and some can’t. UHMW plastic for example is perfect for applying ink or coating in applications where graphic difficulty is limited. But it is too soft for applications involving high screen anilox rolls or precise metering requirements where a fine contact area is required.

Thanks to next-generation polymers like Delrin, Polyether Ether Ketone (PEEK), or glass/Kevlar reinforced materials, there are compositions that are rigid enough to support a fine contact area similar to that of steel. The bonus is these blades are plastic, so they are inherently softer and do not develop a dangerous cutting edge risking injury to press operators.

Making the Switch

Next-generation polymer doctor blades offer the performance of steel blades while providing the safety of plastic blades. The combination of advanced materials and innovative profile (MicroTip, bevel, etc.) design enables these safe doctor blades to perform in demanding applications previously dominated by steel. Substituting a next-generation polymer doctor blade for steel is a great way to produce a high-quality product while maintaining a safe work environment.