The goal of a sheetfed offset printer, like every printer, is to produce printed pieces efficiently and economically. In sheetfed offset coating applications, selecting the right doctor blade will help keep presses running and minimize costs while maintaining a safe pressroom environment. By replacing steel with a TruPoint Orange doctor blade, a sheetfed offset printer can improve coating laydown, extend blade life, reduce pressroom injuries and eliminate anilox roller scoring.

Specialty and work & turn coatings

More and more, companies are using specialty or “effect” coatings to differentiate their brands and create a tactile and visual experience for consumers. However, formulas such as glitter, grit, soft touch, metallics and pearlescents present particular challenges for the printer. These coatings have high viscosities and contain large particles of solids which make it difficult to accurately control the volume being applied.

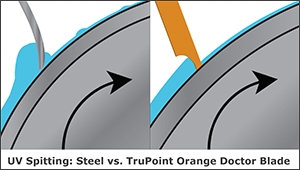

When it comes to work & turn coatings, UV formulas offer significantly higher gloss, better consistency, and improved chemical and abrasion resistance than aqueous formulas. But, again, the application of the more viscous formulas can be difficult to control – their higher viscosities apply extra pressure to the metering blade which causes hydroplaning or “spitting,” especially at high line speeds. In these cases, a specialized blade solution is needed to control the lay-down and minimize coating consumption and waste.

TruPoint Orange with MicroTip

By engineering a modified lamella tip, known as a MicroTip, on an advanced polymer material, Flexo Concepts® has created a doctor blade product that can overcome the limitations of steel in offset coating applications – Orange. The blade can effectively meter UV and specialty coating chemistries, is compatible with all coating formulas and delivers the traditional benefits of plastic blades: blade life and safety.

Better coating laydown

When used to apply UV coatings, the Orange blade material is strong enough to withstand the force of these higher-viscosity formulas without flexing – even at high press speeds. Its controlled metering keeps the coating from sliding underneath the blade and spraying or “spitting’ onto the sheet and surrounding area. The material also has a lower surface tension than steel, decreasing the attraction of the coating to the blade and allowing for a smoother transfer to the blanket.

When used to apply UV coatings, the Orange blade material is strong enough to withstand the force of these higher-viscosity formulas without flexing – even at high press speeds. Its controlled metering keeps the coating from sliding underneath the blade and spraying or “spitting’ onto the sheet and surrounding area. The material also has a lower surface tension than steel, decreasing the attraction of the coating to the blade and allowing for a smoother transfer to the blanket.

Longer blade life

Applying UV coatings and coating formulas that contain pearlescent flecks, glitter, sand or other abrasive particles requires a tough, durable doctor blade that can withstand their harsh properties and the coarse anilox roll surfaces required to transport them. Unlike steel blades, which are subject to accelerated blade wear in these applications, Orange blades are abrasion and corrosion-resistant and offer superior longevity. The blade’s MicroTip has a long, slow wear period and delivers a consistent application of coating for the duration of the job. The blade material is self-lubricating, with a low coefficient of friction to resist mechanical wear, so blade life is extended in every application and presses can run longer.

Improved safety for operators

As steel blades wear, their edges become honed through contact with the anilox roller, leaving razor-sharp tips that can cause serious cuts. Press operators need to be extremely careful and wear protective gloves when removing the worn blades from the press to avoid injuries.

Due to their material composition, Orange doctor blades are safer to handle even when worn. Switching from steel to Orange will reduce lost-time accidents and can save a printer a lot of money in terms of workman’s compensation insurance rates, medical bills, labor replacement expenses and press downtime.

TruPoint Orange won’t damage anilox rollers

Steel blades are also to blame for many cases of anilox roll scoring. Incorrect blade installation or excessive blade pressure can cause small fragments of metal to break away, become trapped against the roller and destroy rows of anilox cells as the roller turns. The score lines run around the circumference of the roller and affect the corresponding areas of coating coverage.

The friction between a steel blade and roller surface can also erode the anilox cell walls, accelerating wear on the surface of the roller. As a result, cell volume is reduced and the anilox roller can no longer transport the precise volume of coating that it was designed to deliver. The printer wastes substrate and coating and has to resurface or replace the roller at a significant cost. Orange blades are constructed from a non-abrasive material and will never score anilox rollers or cause accelerated wear on their surface.

Customizable thickness and tip combinations

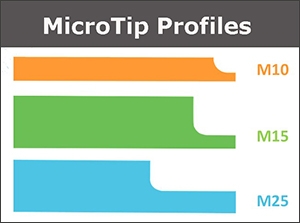

TruPoint Orange blades can be engineered to a full range of size and profile combinations to optimize metering performance with UV and specialty coating formulas. They range in thickness from .7mm to 1.25mm to offer varying degrees of stiffness, rigidity and deflection. Add to this an array of MicroTips, and these blades can be customized for a “perfect fit.”

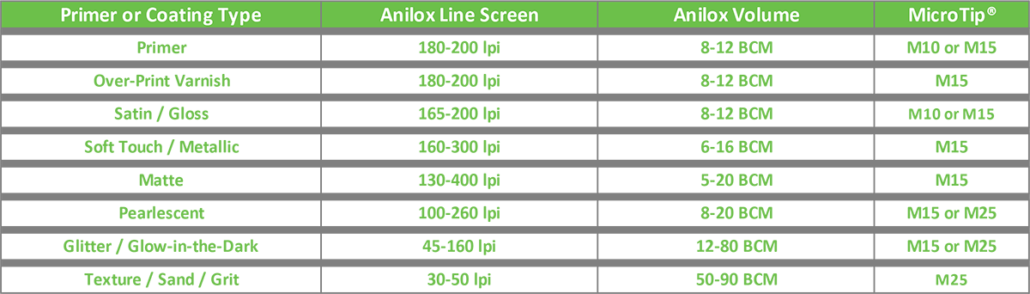

The choice of blade thickness and tip will be determined by the anilox configuration and required coat weight, which is driven by the viscosity and solid load of the coating. Typically, higher line screens and lower cell volumes will require a smaller MicroTip (an M10 or M15 for dull/satin/gloss coatings for example), but as line screens decline and volumes increase, a MicroTip providing a larger contact area (M15 or M25) will perform better. By optimizing their Orange blades with the appropriate MicroTip, printers are also able to achieve longer blade life in these applications than with steel.

The choice of blade thickness and tip will be determined by the anilox configuration and required coat weight, which is driven by the viscosity and solid load of the coating. Typically, higher line screens and lower cell volumes will require a smaller MicroTip (an M10 or M15 for dull/satin/gloss coatings for example), but as line screens decline and volumes increase, a MicroTip providing a larger contact area (M15 or M25) will perform better. By optimizing their Orange blades with the appropriate MicroTip, printers are also able to achieve longer blade life in these applications than with steel.

Doctor blade optimization

The TruPoint Orange doctor blade with MicroTip edge technology helps sheetfed offset printers optimize their coating process by offering an effective, longer lasting and safe doctor blade option for a full range of coating applications. Choosing Orange to handle aggressive formulas, minimize blade changes, and reduce waste, mess and injuries can not only simplify the job of the press operator but also significantly enhances a printer’s bottom line.