Solutions For Lithium-Ion Battery Production

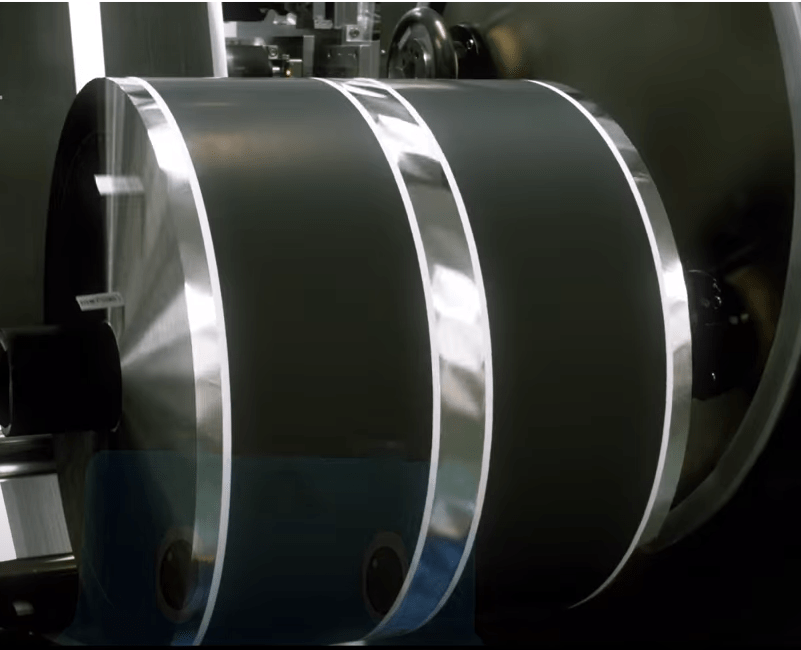

In Separator Film Manufacturing, Electrode Coatings Application, and Calendar Roll Cleaning, the common thread is the need for a plastic doctor blade. The utilization of steel doctor blades poses risks to the lithium-ion production process and the final product’s safety. With steel blades, the gradual wear introduces metallic micro-particles, causing contamination that can lead to thermal runaway. This, in turn, jeopardizes the storage and performance of lithium-ion batteries.

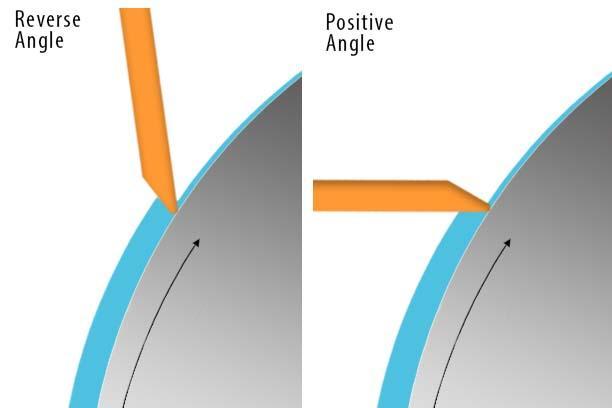

Common Doctor Blade Configurations

Although lithium batteries are a new technology, the methods being used for applying coatings during their production process are time tested. Both reverse angle and positive-angle metering blade configurations are used In either direction, high performance polymers with great stiffness and wear properties are required to coat consistently and reduce the number of blade changes.

The TruPoint Doctor Blade Advantage

Plastic doctor blades — inert and non-conductive materials that guarantee a seamless and safe production process for your lithium-ion applications. Flexo Concepts produces a number of doctor blade products ideal for production of high-quality Lithium-ion batteries.

Order TruPoint Doctor Blades Today!

With FC Marketplace, you can price, order, track and pay for your TruPoint Doctor Blades online. Real time quoting and material availability, access to a detailed purchase history, and live customer service chat are just a few of the features currently available. Transactions can be done in USD, Euro, and British Pounds. Access to the FC Marketplace for existing and new customers can be requested with this form.