Doctor Blades for Narrow Web Printing

What is Narrow Web Flexographic Printing?

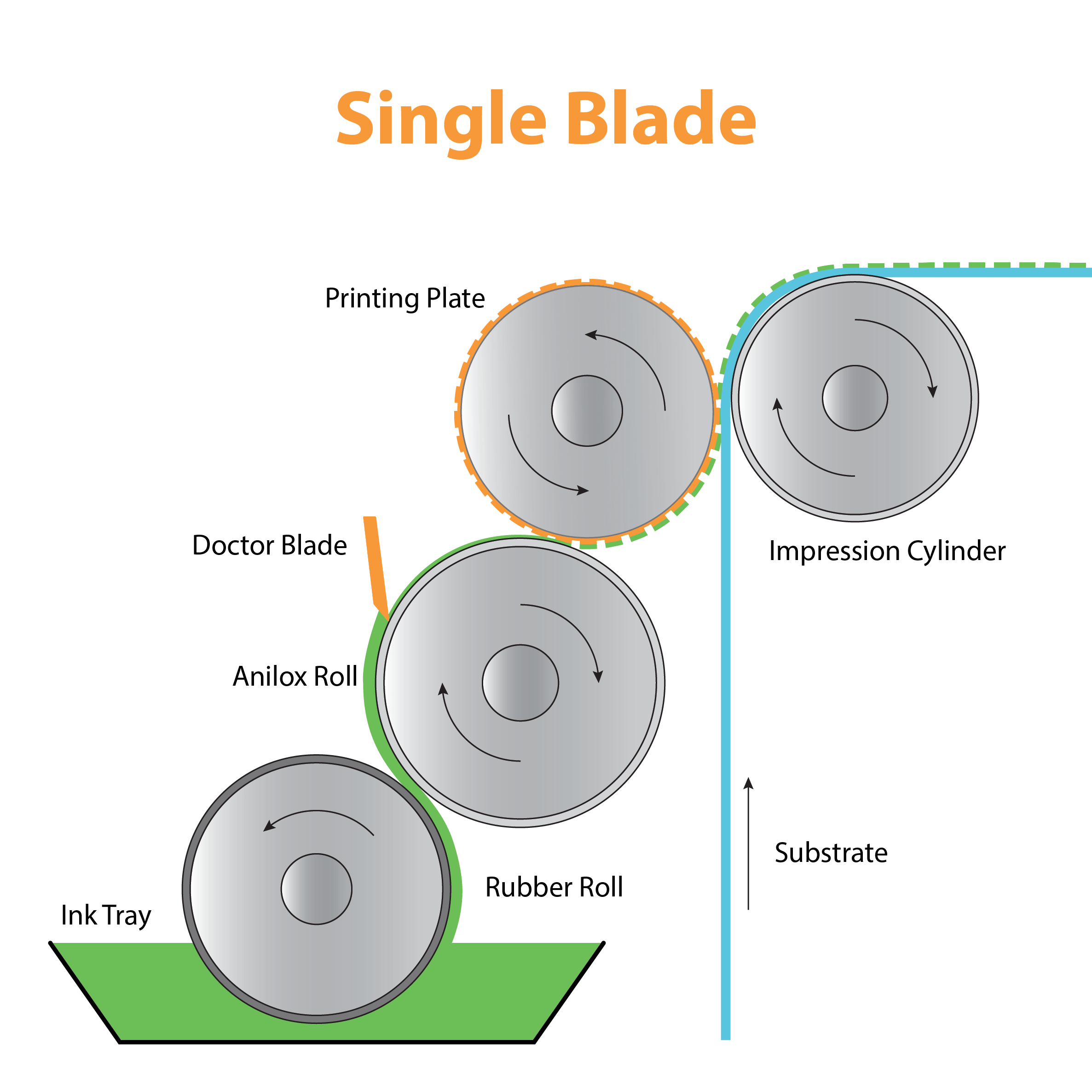

In narrow web flexographic printing, a doctor blade wipes excess ink from the anilox roll so only the correct amount of ink transfers to the printing plate, ensuring clean dots and consistent color, especially during high-speed runs. Choosing the right blade — such as TruPoint® PolyLam XL with MicroTip™ technology — improves ink control, reduces anilox wear and scoring, enhances pressroom safety, and delivers reliable performance with white inks, primers, and coatings compared to traditional steel blades. Proper blade selection also helps minimize downtime, maintain stable print density, extend anilox life, and improve overall press efficiency.

What does a doctor blades in narrow web printing do?

In narrow web flexographic printing, a doctor blade meters ink by wiping excess ink from the anilox roll so only the correct amount transfers to the printing plate. This process ensures clean dots, consistent color, reduced anilox wear, and stable print quality at high press speeds.

Why is blade choice important?

The right blade improves ink control, reduces anilox scoring and wear, enhances pressroom safety, and minimizes press stops by stabilizing print density and lowering maintenance.

Why Use Polymer Doctor Blades in Narrow Web Printing?

TruPoint Polylam XL doctor blades are preferred in narrow web printing because they:

-

Deliver more consistent metering than steel

-

Reduce anilox damage and scoring

-

Improve pressroom safety

-

Perform reliably with white inks, coatings, and primers

Frequently Asked Questions

- What doctor blade do you reccomend for my narrow web press?

TruPoint Polylam XL featuring microtip technology - What is a doctor blade in narrow web printing?

A doctorblade that wipes excess ink from the anilox roll so only the correct ink volume transfers to the plate. It’s essential for stable ink metering, ink control, and print quality. - How does a doctor blade impact print quality for Narrow Web Pressrooms?

The doctor blade’s material, profile, contact angle, and pressure directly influence ink film thickness and consistency. A cleaner wipe means sharper images, reduced dot gain, and fewer defects. - Why Switch from steel to polymer doctor blades?

Polymer doctor blades improve safety, limit anilox wear, and deliver more consistent metering over long runs, especially helpful with delicate label substrates and high line screens. - Can I test Polylam XL Doctor blades before committing?

Yes, you can trial TruPoint Polylam XL on your press , we will ship you a free sample to install on your press. - When should I choose TruPoint Orange verses TruPoint PolyLam XL doctor blades?

Use TruPoint Orange to solve targeted print issues, and use PolyLam XL when you want a reliable, all-around blade that replaces steel and performs across your full narrow-web operation.

Skip to content

Skip to content