过去,钢刮刀片是制作高端图形的唯一选择,但印刷商不得不面对使用这种材料所带来的刮刀寿命缩短和印刷车间伤害等问题。现在不一样了!材料技术的最新创新和 尖端工程 终于研制出了可与钢刮刀相媲美的聚合物刮刀,同时也解决了印刷车间的一些常见问题。

过去,钢刮刀片是制作高端图形的唯一选择,但印刷商不得不面对使用这种材料所带来的刮刀寿命缩短和印刷车间伤害等问题。现在不一样了!材料技术的最新创新和 尖端工程 终于研制出了可与钢刮刀相媲美的聚合物刮刀,同时也解决了印刷车间的一些常见问题。

Steel doctor blades are thin and rigid which allows them to achieve a fine contact area with the anilox roll. A fine contact area is required for the blade to achieve an effective wipe on high line screen rolls used in more demanding graphics applications. Traditional plastic doctor blades, on the other hand, have long been preferred for their longer life in less demanding graphics applications. Plastic blades had to be engineered thicker in order to provide enough rigidity to maintain good contact with the anilox roll and achieve a sufficient wipe. The thickness and larger contact area prevented these blades from being effective when used to meter mid to high line screen rolls. While they lasted significantly longer and were safer to handle than steel blades, they tended to leave more ink on the surface of the roll; this produced dot gain and poor image quality in the printed piece.

钢刀的缺点

钢刀的缺点

Despite its reputation for being the superior metering material, steel has many disadvantages. The blades wear quickly and need to be replaced frequently. Operators are also exposed to cut hazards when removing the worn blades from the press, and the metal fragments can come loose and score anilox rolls. The environmental impact of using steel can also be significant. There are huge energy costs associated with the manufacture of steel blades as well as anilox resurfacing, and additional station clean-ups generate a lot of contaminated waste. Despite these drawbacks, steel was believed to be the only doctor blade option to execute a clean wipe on a high line screen anilox roll, leaving printers no choice.

新型聚合物刮刀

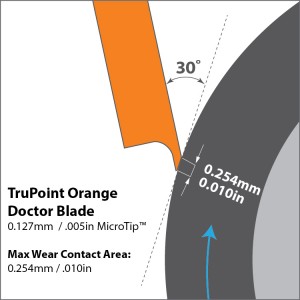

Today, specially formulated polymer doctor blades offer the best of both steel and plastic. Unlike traditional plastic doctor blades, the next generation material allows for a precisely engineered micro-tip which wears slowly and evenly throughout the life of the blade. The micro-tip edge allows the blade to achieve a fine contact area with the anilox roll and deliver effective metering on line screens up to 2000 lpi or 785 L/cm. The long and steady wear period of the next generation polymer doctor blade maximizes press uptime and allows for consistent ink film thickness for the duration of the print job.

Compared to steel, the polymer material does not develop a dangerous cutting edge after use, and the worn blades are safe to handle. Also, the material will not separate, splinter or crack and produces no metal fragments that can lodge between the doctor blade and the anilox roll. A reduction in anilox scoring means better image quality, less downtime, less waste and lower roll replacement costs.

Polymer doctor blades have come a long way in recent years. A combination of advanced materials and a micro-tip edge has produced revolutionary new doctor blade option for printers: a blade that can compete with steel in the most demanding graphics applications while retaining the safety and blade life benefits of traditional plastic.