Doctor blade chamber leaks are costly in terms of downtime and waste. While failed end seals are responsible for a large number of chamber leaks, ill-fitting doctor blades can also contribute to leaks. Ordering cut-to-length doctor blades from your supplier is a smart way to reduce leaks, maximize doctor blade and end seal performance and save a printer thousands of dollars every year.

Doctor blade chamber leaks are costly in terms of downtime and waste. While failed end seals are responsible for a large number of chamber leaks, ill-fitting doctor blades can also contribute to leaks. Ordering cut-to-length doctor blades from your supplier is a smart way to reduce leaks, maximize doctor blade and end seal performance and save a printer thousands of dollars every year.

Problems arising from Chamber Leaks:

- Ink waste

- Substrate waste

- Excessive solvent consumption for clean-ups

- Downtime for change-overs

- Reduced doctor blade life

- Scored anilox rolls

- Increased end seal consumption

Chamber leaks are a nuisance in the pressroom that cause frustration and reduce press efficiency. When faced with a leaking chamber, a press operator has to stop the press and clean up the mess. Often, he will try to fix the problem by increasing the load pressure instead of looking for the basic cause of the leak. While this may work as a temporary solution, it can lead to other problems such as accelerated doctor blade and anilox wear. The increased pressure may also force ink out of the ends of the chamber, making the situation worse. Paying a little extra attention when installing doctor blades and ends seals can prevent many leaks from occurring in the first place.

Causes of Chamber Leaks:

Causes of Chamber Leaks:

- Improper seal material

- Bad seal design

- Lack of proper seal lubrication

- No dead bands on anilox rolls

- Anilox roll chips

- Incorrect doctor blade length

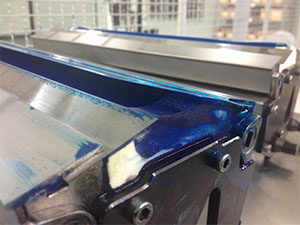

Failed end seals account for many chamber leaks. Using an end seal material that is not compatible with the type of ink being used, the length of the run or the press speed will allow ink to escape from the ends of the chamber. Ink build-ups can result from not using the appropriate lubrication to reduce friction between the anilox roll and end seal. If the seals are not a proper fit, they will not do their job at containing ink within the confines of the chamber. Working with your end seal supplier is a good way to work through these issues and ensure that you are using the correct end seals for your application. (View End Seal Brochure)

The condition of the anilox roll can also play a role in chamber leaks. If the roll lacks a dead band (an unengraved area) at each end, ink will build up there and cause the seals to fail. Chips on the ends of the anilox rolls can also create ink buildup and compromise the integrity of the end seals.

Incorrect Doctor Blade Length can cause Chamber Leaks

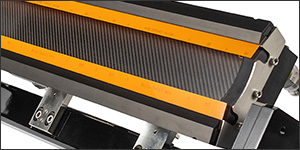

In addition to failed end seals and defects in the anilox roll, doctor blades that are too short or too long

can be another source of leaks. When changing a doctor blade, it’s important to make sure that the new blade is the right size for the chamber and installed correctly. If it’s not a perfect fit, the doctor blade provides a gap through which ink can leak out of the chamber.

When properly installed, the doctor blade should have some upward pressure from the end seals to ensure a sufficient seal. A very slight rise in the blade is okay, however, extra loading pressure should not be necessary to get the blade to wipe the center of the anilox roll.

When a blade is too short or too long for the chamber, it prevents the end seals from doing their job. The blade should come to about halfway across the tops of the end seals when placed in the chamber. If the blade does not reach the seals, then the seals can actually prevent contact between the doctor blade and the anilox roll.

On the other hand, if the blade extends beyond the outer edge of the end seal, it may create a small opening between the underside of the blade and the end seal which creates a path for ink to flow out of the chamber. If it’s too long, the blade may also become wavy and not lie flush with the roll, causing uneven metering and leaking.

Installing doctor blades that are a perfect fit for the chamber will eliminate this source of leaks. When ordering doctor blade material by the roll, it is important to confirm the proper blade specifications with your chamber OEM to make sure that press operators are cutting blades to the correct length. An easier way to ensure the proper size is to order cut-to-length doctor blades from your supplier that are ready to install right out of the box.

Cut-to-length Doctor Blades can Reduce Chamber Leaks

Doctor blades that are the incorrect size for the chamber can be a frustrating source of chamber leaks, downtime and waste. Installing blades correctly and making sure that they are the precise length according to OEM specifications is one way to prevent this problem. Ordering cut-to-length doctor blades from your supplier will not only speed up blade changes but also ensure a perfect fit to maximize blade performance and minimize leaks.